Fast Sheet Former (press + drier) services|FluidForming Americas • Hydroforming Reinvented : manufacture Forming & Rolling. Our state-of-the-art precision press brakes contain a unique up-acting design to eliminate part canoeing and consistent production quality. Learn More webSport Huancayo scores with the latest results, fixtures and tables. View up-to-date results live as they happen.

{plog:ftitle_list}

webCeltic x Kilmarnock. Premiership, sábado, 17 de fevereiro de 2024. Aqui está nosso palpite Celtic x Kilmarnock e prévia do jogo. Com base em nossa análise detalhada .

Get custom formed sheet metal parts for rapid prototyping and production in as fast as 3 days. Online quoting and ordering with DFM included in each quote.FluidForming is a cost-effective sheet metal forming process designed for rapid prototyping & low- to medium-volume production. 800-497-3545.

Forming & Rolling. Our state-of-the-art precision press brakes contain a unique up-acting design to eliminate part canoeing and consistent production quality. Learn More3. You’re covered. From prototype to production, you’re covered. Complex design? No problem. Exacting standards? We’ve got it. We have the technology, equipment, and expertise to .

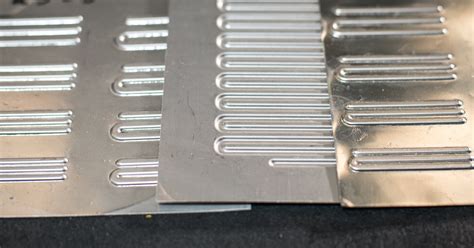

Metalworking Solutions is a leader in sheet metal forming services, including bending material with our advanced press brake equipment. We also provide full-service metal fabrication, machining, welding, and finishing services.Sheet hydroforming is a metal fabrication technique that leverages pressurized fluid to form and shape ductile metal into desired components using pre-shaped plates or dies. As part of this process, a flat metal disc —known as the blank— . Fathom understands the demand for rapid sheet metal services that lower cost and meet deadlines. In some cases, no machining or tooling is needed. By leveraging .Precision sheet metal hydroforming for rapid prototyping & volume parts production. FluidForming is the most precise, repeatable, and accurate sheet metal hydroforming process available to manufacturers for low- to medium .

Whether it’s simple brackets or complex structures, we can deliver. Furthermore, our services encompass design and engineering support, metal cutting, bending, welding, painting, and finishing. Additionally, we offer rapid prototyping and .

A Versatile System For Paper-Making In the Laboratory. An instrument which produces test sheets with the similar properties and fibre orientation as paper made on full-size machines. A Dyna mic She et Fo rmer (DSF) pr ovide s the m eans o f making large hand-sheets of paper and board, which are then used for research into paper properties, grade development and .

Paper sheet former that creates single to multilayered sheets using different pulp types (contains four separate stock chambers).The dynamic sheet former is designed for the production of rectangular sheets of large dimensions 300x900 mm in the laboratory with similar conditions of paper machines. This system allows obtaining sheets with different fiber orientations .Rapid-Köthen Sheet Former Conforms to the following standards ISO 5269-2 . Paper Sheet Press (Pneumatic) Price on quotation. Find Out More; We’re here to help . +44 01522 401375 [email protected] About & Support . About Meet The Team Advice & Guides News Contact FAQs. Services . Calibration / Repair. Testing Equipment . By Instrument By .SKZ196 Fiber oil fast extractor; SKZ199 Color Match Cabinet; SKZ200 Oxygen Index Detector; SKZ1042 Hydrostatic pressure resistant Tester; SKZ1048 Textiles Airflow Resistance Tester; Testing Instruments for Plastic. SKZ063 Plastic slice Cutter; SKZ120 Haze Meter; SKZ127B Thickness Meter; SKZ142 Dumbbell Sample Cutter; SKZ145 Melt Flow Indexer .

Arizona Biltmore Fact Sheet PROPERTY NAME ADDRESS RESORT OPENING TOTAL NUMBER OF ROOMS LAST PUBLIC VENUE RENOVATION . restoring its signature “Biltmore Block” and long-standing design to former glory. . dry cleaning services, luggage and bell service, and press reader. access. The resort’s ultramodern, 3,000 square-foot fitness center .The TD-RK is a laboratory sheet dryer designed to be used along with any Rapid Köthen type Laboratory Sheet Former. This newly designed dryer meets all specifications of applicable standards and replaces traditional Rapid-Köthen drying stations saving laboratory space and maintenance costs.Sheet Dryer for fast drying of wet paper pulp sheets mainly from laboratory sheet former according to TAPPI or SCAN standards. . Manual Sheet Former – TAPPI T205. Price on quotation. Find Out More; Paper Sheet Press (Pneumatic) Price on quotation. Find Out More; Chip Classifier. Price on quotation. Find Out More; We’re here to help.The Rycolab Rapid-Köthen Automatic Sheet Former is used for the production of standardized paper sheets in the laboratory (ø 200 mm). Four models available: with 1, 2, 3 or 4 dryers: RL-ASF-1-A: 1510 x 860 x 1450 mm (WxDxH) + with KWT: 1840 (H)

Provides the means of making large hand sheets of paper and board, which are then used for research into paper properties, grade development and a comprehensive testing of paper quality. The test results permit optimization of the pulp before it is introduced to the full-size production paper machine.FastForming.com completes its’ .4 million expansion with a new MAAC 5×9 three station rotary forming machine and a DMS 5×5 twin table 5 Axis router. Contact us for your high production needs. Our Location. FastForming.com, LLC 300 Morning Star Drive Rittman, OH 44270 (330) 927-3277. Popular Pages. Home;SKZ Industrial SKZ125 Fast Sheet Former (press + drier) new. Manufacturer: SKZ Industrial Character Automatic type hand sheet former, small dimension more precision and easy to operate, especially get rid of the air-pressure of traditional sheet former.Its sheet diameter Φ200, stainless steel cycle w.

This former combines vacuum-sucking & forming, pressing, vacuum-drying into one machine, and all-electric control. Product Features 1) Sheet-forming and vacuum-drying are combined into one machine; 2) White water recycling; 3) Electric pulp-feeding; 4) Compressed air to even the pulp, manual even the pulp, drain out the water fast;This former combines vacuum-sucking & forming, pressing, vacuum-drying into one machine, and all-electric control. Product Features 1) Sheet-forming and vacuum-drying are combined into one machine; 2) White water recycling; 3) Electric pulp-feeding; 4) Compressed air to even the pulp, manual even the pulp, drain out the water fast;The HAAGE Sheet Former BB is the affordable alternative to the HAAGE Sheet Former BBS. It can also be equipped with 1 - 4 dryers. It can also be equipped with 1 - 4 dryers. By ways of manual control of the sheet formation and drying processes, it produces fast and reliable test sheets from pulps, mechanical pulps, pulp mixtures, and raw .

ANDRITZ is one of the leading suppliers for market pulp producers. ANDRITZ has completed numerous successful pulp sheet drying projects and plant upgrades all over the world. ANDRITZ provides turnkey market pulp drying plants, as .2024 session fact sheets The Minnesota Legislature and Governor Tim Walz made careful investments in 2024 to address the most immediate needs in human services. Human services budget: Focusing on immediate priorities (PDF) July 2024; Expanding behavioral health care capacity, improving access (PDF) July 2024

Sheet Metal Prototype Services at Prototek

Sheet Metal Forming • FluidForming Americas

BN-8053-01A Laboratory Papermaking Pulp Hand Sheet Former (water cycle sheet former )is a paper sheet forming machine used by the papermaking laboratory to make paper pulp. This machine is fast, stable and reliable, with small size, convenient for disassembly and operation, white water circulation, electric water supply, aerodynamic bubble .

Adirondack Machine Corporation 84 Boulevard Street Hudson Falls, NY 12839 518-792-2258 518-792-2274 - Fax E-mail:Section 13(b)(1) of the FLSA provides an overtime exemption for employees who are within the authority of the Secretary of Transportation to establish qualifications and maximum hours of service pursuant to Section 204 of the Motor Carrier Act of 1935, except those employees covered by the small vehicle exception described below.

Sheet Metal Forming and Bending Service

The SF-RK is an automatic sheet former used for the production of laboratory sheets in accordance to the Rapid Köthen method for measurement of the physical and/or optical properties of pulps. This equipment became standard for the Q.C. (quality control) and for R&D (research and development) due to its sturdiness, precision, reliability and .

Sheet Metal Fabrication

A pneumatic mixer, with an integrated pressure regulator, in the stock container base ensures perfect mixing of pulp suspension and homogeneity of sheets. White water Recirculation System enables sheet formation in accordance to ISO 5269/3 whereas sheets are formed using white water, simulating the close loop existing in real paper machines.Apparatus with 205mm diameter forming column and dryers. Quick equipment with no intervention of the operator needed in the sheet production. There are two types: manual and automatic. Possibility to choose white water recirculation system to produce sheets with water already used in other sheet formations.Sheet Former with 1 vacuum dryer approx.172 (w) x 74 (d) x 86 (h) cm Sheet Former with 2 vacuum dryers approx.172 (w) x 74 (d) x 86 (h) cm Sheet Former with 3 vacuum dryers approx.214 (w) x 74 (d) x 86 (h) cm Sheet Former with 4 vacuum dryers approx.256 (w) x 74 (d) x 86 (h) cm Special Constructions Single sheet forming columns forWe have developed many products, such as 23L beater, Aquapulper, Fiber classifier, flotation deinking machine, Handsheet Former, Rotary Digester, Oxygen bleaching digester, rapid sheet dryer, hydraulic press, Roller squeezing machine, Lab plup screen, washing machine, three sections of centrifugal vacuum pump, PFI Beater (vertical beater .

DESCRIPTION: Description: Scotia Depot was built in 1942-43 and was commissioned as a Navy facility on March 30, 1943, located in Scotia/Glenville, New York (NY-20). It was a storage/ supply depot for naval forces along the Atlantic coast and Europe, and as a storage and distribution point for National Stockpile materials. The parcel originally consisted .

Rapid Sheet Metal

Standards: ISO5269/2-Part two: the fast sheet former method. It contains one paper-making equipment and two drying equipment. Feature: 1.Mainly composed by d.

19/out/2023 - Explore a pasta "toca life imprimir" de ♡Evizinha♡ no Pinterest. Veja mais ideias sobre ideias para casa de bonecas, modelo de boneca de papel, roupas de .

Fast Sheet Former (press + drier) services|FluidForming Americas • Hydroforming Reinvented